What Digital Twins Actually Are

Cutting Through the Jargon

At its core, a digital twin is a virtual replica of a physical object, system, or process. It’s not just a 3D model it’s a live, working simulation that reflects real time conditions and behaviors.

Simply put:

A digital twin mimics something that exists in the real world

It updates in real time as changes happen to the physical counterpart

It’s used to test, analyze, and optimize without disrupting the actual system

How Digital Twins Mirror the Real World

Digital twins don’t just copy how things look they simulate how things work. The virtual model is continuously fed with live data from the real world, enabling it to reflect changes and predict future scenarios.

This means:

A machine’s digital twin shows wear, performance, and stress levels as they occur

A facility’s twin can model logistics flow, equipment efficiency, and potential breakdowns

A process twin (like a supply chain) simulates demand shifts, bottlenecks, and delivery accuracy

Technologies Powering Digital Twins

Several key technologies work together to bring digital twins to life:

Internet of Things (IoT): Connects physical objects and collects real world data through embedded sensors

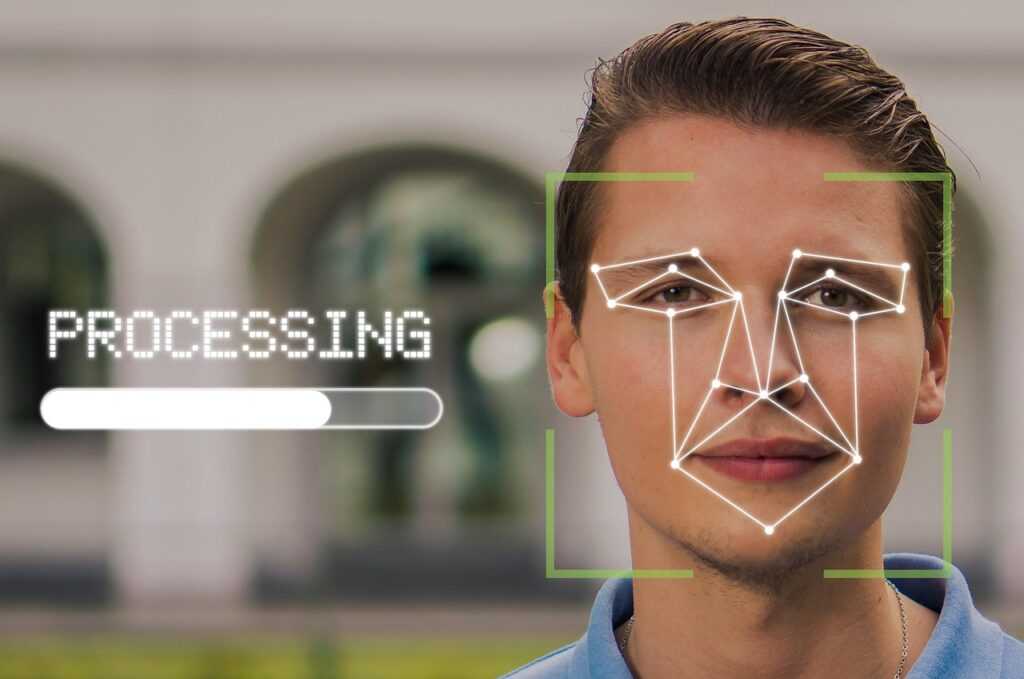

Sensors and Actuators: Provide granular, real time data from machines, environments, or people

Simulation Engines: Run complex models that mirror real world reactions and outcomes

Real Time Analytics: Process data instantly to generate insights, alerts, and predictions

Combined, these technologies give digital twins their strength: the ability to test ideas, pinpoint issues, and forecast outcomes all with less risk and more precision.

How Industries Are Actually Using Them

Digital twins aren’t just tech hype they’re quietly becoming the backbone of smarter, leaner operations across sectors.

In manufacturing, companies are using digital twins to monitor machines in real time. No more waiting for things to break. Sensors feed live data into digital mirrors, flagging issues before parts fail. Predictive maintenance means less downtime, tighter schedules, and fewer costly surprises.

The energy sector is using digital twins to fine tune grid performance. Operators can run safety simulations without touching live infrastructure. That reduces risk and uncovers weak points while keeping power flowing.

In logistics, digital twins track inventory across the supply chain. From warehouse layouts to route planning, the virtual models help companies move goods faster and with fewer bottlenecks. It’s all about squeezing inefficiencies out of the system.

Healthcare isn’t staying behind. Surgeons are mapping detailed digital versions of individual patients to plan procedures. Hospitals simulate treatments and optimize resource use based on real time patient data. It’s personal health with industrial grade precision.

And in urban planning, digital twins help model traffic, utilities, and infrastructure. Cities can test new roads, zoning changes, or transit plans digitally before breaking ground. Think of it as a sandbox for smart development with real world impact.

Why They’re a Game Changer

Digital twins cut waste. In sectors where downtime costs thousands per minute, being able to simulate failures or foresee wear and tear can mean the difference between smooth output and a total halt. By mirroring physical systems in real time, teams can spot issues early and act before they turn into expensive problems.

The cost savings go deeper than maintenance. Running simulations lets engineers and planners test ideas virtually whether it’s a new machine layout or a schedule change without risking real world resources. No materials wasted, no production paused. Just smarter, faster iterations.

They also make decisions smarter. Operators aren’t guessing anymore; they’re acting on live data and models that constantly update based on what’s happening on the ground. Whether it’s adjusting operations in a wind farm or rerouting a shipment, decisions become faster and more accurate.

And safety? That’s a major win. High risk environments like chemical plants or surgical planning rooms can test insane conditions without endangering a soul. Digital twins give industries a sandbox to experiment in, without the real world risk.

The Link Between Digital Twins and AI

Digital twins on their own can do a lot but pair them with AI, and they move from reactive to predictive. With AI in the mix, digital twins don’t just mirror what’s happening; they start forecasting what’s coming. Think predictive maintenance, anomaly detection, or pattern recognition that spots the warning signs before there’s even a blip in system performance.

This connection creates a learning loop: the digital twin gathers more real time data, the AI gets better at spotting trends, and decisions get sharper over time. It’s not about one system doing all the heavy lifting it’s about a tight feedback cycle where both continuously improve.

This is exactly where AI tools in industry earn their keep. From generative models training simulations to reinforcement learning optimizing processes, AI powers the smart side of digital twins. And as AI technology advances, the virtual models only get smarter. The smarter they get, the more accurate and valuable they become in high stakes environments like factories, energy networks, or even emergency response systems.

Use Cases That Prove the Value

Digital twins aren’t just theory they’re delivering measurable results across industries. Here are three real world examples where digital twin technology is driving serious impact:

Cutting Production Errors in Automotive Manufacturing

A global car manufacturer implemented a digital twin of its entire assembly line. The result?

50% reduction in production errors

Real time monitoring of each system component

Predictive adjustments to machinery settings before issues occur

Continuous feedback loop between digital model and physical operations

By simulating assembly workflows and stress testing them virtually, the company now resolves issues before they affect the end product.

Predicting Critical Failures in Power Plants

In the energy sector, a major power plant created digital replicas of turbines and other mission critical components. These twins collect ongoing sensor data, and use predictive analytics to forecast wear and failure.

Operators receive weeks long lead time to address component risks

Unscheduled outages have decreased sharply

Maintenance teams now prioritize upgrades based on actual performance risk, not just periodic schedules

This proactive model greatly reduces downtime and boosts energy reliability.

Simulating City Traffic for Smarter Urban Planning

Urban engineers are turning to digital twins to model entire city districts. In one pilot case, planners simulated five years of traffic conditions in just a few minutes.

Tested road designs and traffic signals before physical implementation

Identified unexpected bottlenecks in previously unexamined areas

Improved emergency response routing across various real world scenarios

The result is more resilient, efficient infrastructure designed with real data not just theoretical models.

These use cases underscore the real world potential of digital twins. They’re not future promises they’re here, and they’re making a difference where precision and prediction matter most.

A Look Into the Next Phase

Digital twins are evolving fast, and three technologies are giving them a serious upgrade: edge computing, blockchain, and immersive environments like VR and AR. Each one brings more speed, security, and realism to the table.

Edge computing puts processing power closer to the data source think factory floor instead of centralized cloud. That means faster decisions, near zero lag, and real time action. Useful when the stakes are high, like in a turbine failure or a live logistics bottleneck.

Blockchain joins the ecosystem by locking in data integrity. Digital twins require reliable, traceable inputs especially in complex operations with lots of stakeholders. Blockchain ensures that the data feeding simulations and automations stays clean, trackable, and tamper proof.

Then there’s immersion. With VR and AR plugged in, digital twins aren’t just data models anymore they’re spatial, intuitive, hands on. Engineers can walk through a factory’s future layout. Doctors can rehearse complex surgeries in simulated environments built from real patient data. Immersion turns insight into muscle memory.

Pulling these forces together is the tightening link with AI tools already transforming industry. As seen in platforms like AI Tools in Industry, AI adds autonomy. Systems start thinking for themselves simulating fixes, adjusting operations, even calling in maintenance before humans need to step in. This convergence is turning digital twins from smart dashboards into fully autonomous, adaptive systems.

In short, we’re past the demo phase. Digital twins are growing up faster, smarter, and more action driven than ever before.

What to Watch

As digital twins become more central to industries, cracks are forming beneath the glossy front. First cybersecurity. Digital twin ecosystems are built on real time data flows between physical devices and virtual replicas. That makes them prime targets. A breach doesn’t just risk data loss it can disrupt physical systems in real time, from factory floors to hospital operating rooms. The complexity of these interconnected environments means old school firewalls aren’t enough. Threat surfaces multiply with every sensor added.

Next up: data ethics. Digital twins thrive on monitoring machines, logistics, cities, and in some cases, people. But how far is too far? Tracking energy output is one thing. Tracking employee behavior every second of the day is another. Without strong governance, this level of surveillance walks the line between optimization and overreach. Transparency and consent can’t be afterthoughts.

Finally, the rising question: who’s really in charge? As digital twins grow smarter through AI integration, there’s a growing risk of over relying on automated decisions. In complex systems especially in healthcare, energy, and public safety human oversight still matters. AI can surface insights, but judgment and accountability need to stay in human hands.

This isn’t about slowing down. It’s about building smart, robust systems you can trust. Because in the end, it’s not just code and data it’s lives, dollars, and infrastructure on the line.

Sharone focuses on how modern icons and symbols impact user experience in everyday software. At flpsymbolcity, she works on research-based content that explains the meaning, design logic, and usability of tech symbols across platforms. Her goal is to simplify symbol usage for designers, developers, and everyday users.

Sharone focuses on how modern icons and symbols impact user experience in everyday software. At flpsymbolcity, she works on research-based content that explains the meaning, design logic, and usability of tech symbols across platforms. Her goal is to simplify symbol usage for designers, developers, and everyday users.